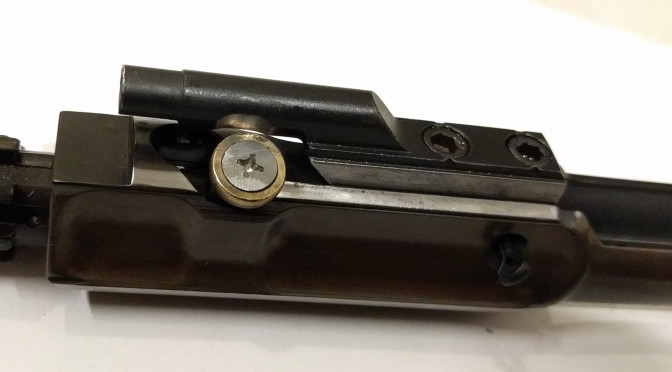

Some time ago I acquired a roller cam pin to my AR-15. Gas key had to be machined to match the new round cam pin, but that was not an issue as I had planned to give my bolt carrier some diet in a form of tender milling from my trusted gunsmith. (Final weight for bolt carrier is 173 g.)

My roller cam pin had one problem though. The screw that was supposed to hold the brass roller in place had a tendency to loosen up and then jamming itself against gas key.

Original screw was completely flat, without any screw drives. I did not had adequate tools and strong enough thread lock to hold the screw in tightly.

I contacted the roller cam pin manufacturer and they offered to fix it for me. They apparently have some adhesive to semi-permanently attach the screw to rest of the cam pin.

I, being more of an DIY-guy, opted to fix the roller cam pin myself.

After two iterations I was finally happy with the solution.

It may not be the best possible steel strength for this particular application, but the brass roller leans against small bulge in the cam pin, so the screw don’t have to take any force coming from side. It just has to hold the roller in place and avoid any contact with gas key.

Time: 1 hour

Tools used: one random M4 screw, hand-file, cordless drill, hacksaw, PH2 head screwdriver and “Extra hard thread lock”