There is always that one particular brand, type or batch of shotgun ammunition that does not work with semiauto shotguns. Some shotguns are more picky than others and even same shotgun models some individual guns cycle same ammunition that other guns struggle with.

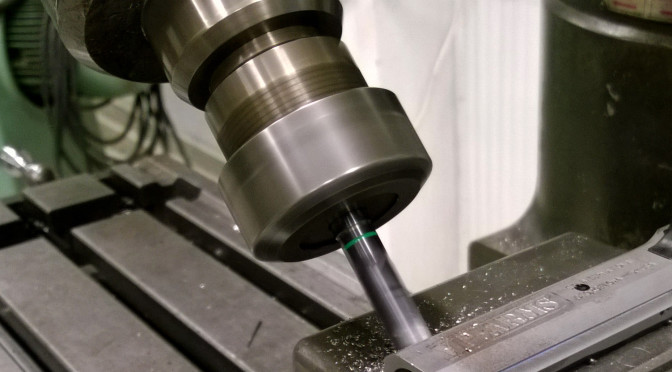

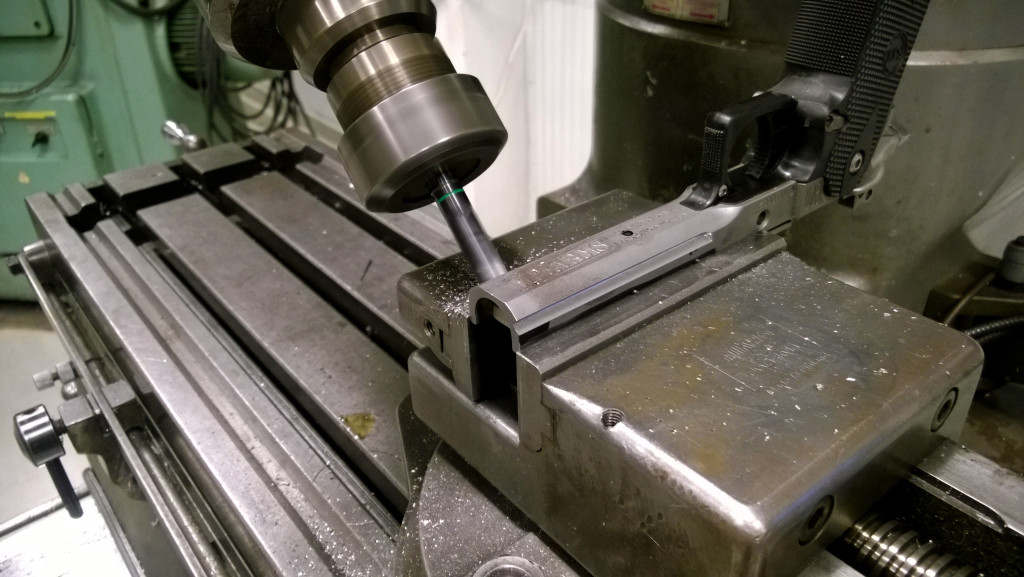

For DIY person it’s tempting to fix this uncertainty. Naturally lapping the bolt carrier rails, polishing all metal-to-metal contacts will help the gun to cycle. With gas operated shotguns drilling gas ports slightly larger might also help.

After doing all above I still found that there exists ammunition that does not cycle reliably with my Baikal MP-153. Mostly really old 24g skeet and trap ammunition. Some may ask that why bother? Those asking that question don’t get the tickling sensation when fixing something makes things better.

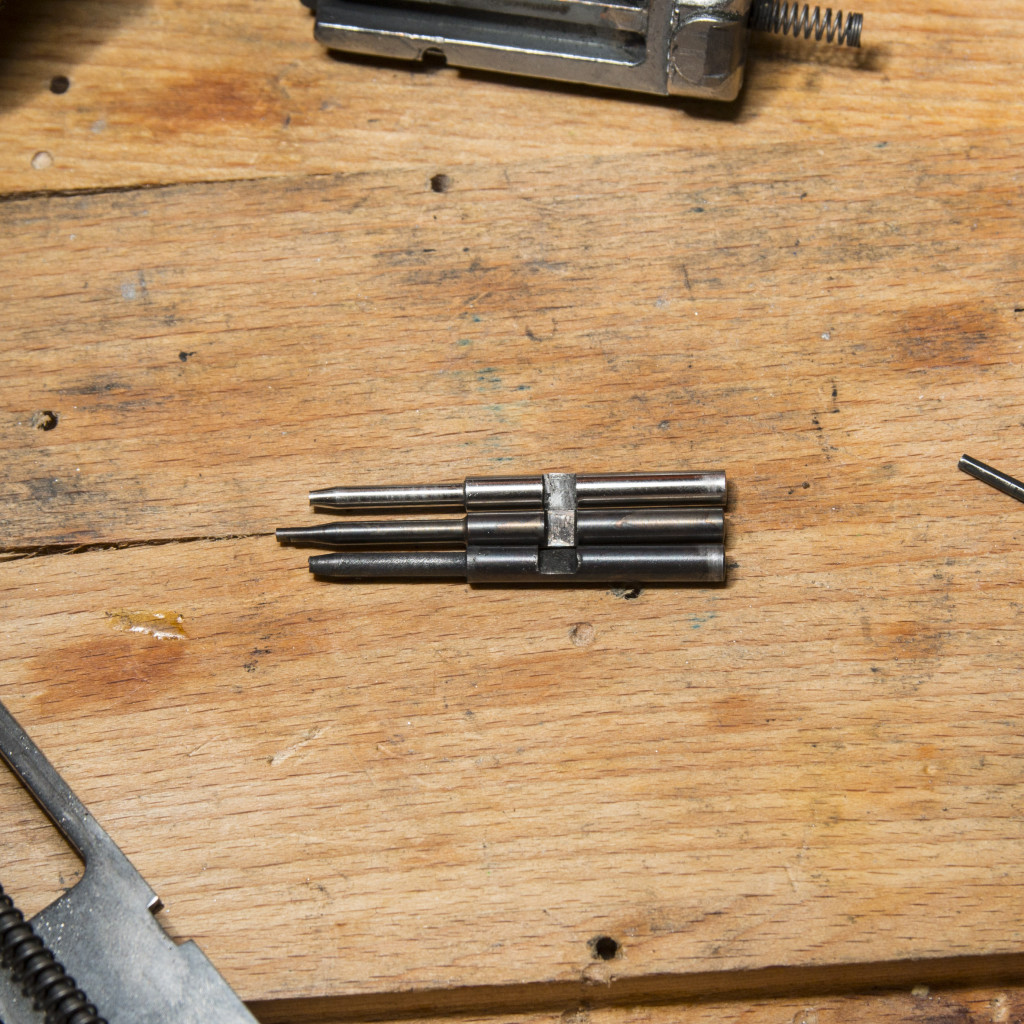

Continue reading Speed Cycling and reliability mod for Baikal MP-153