The manufacturer seen some of the pictures and they insisted that the non-milspec hammer/trigger was the issue causing light strikes.

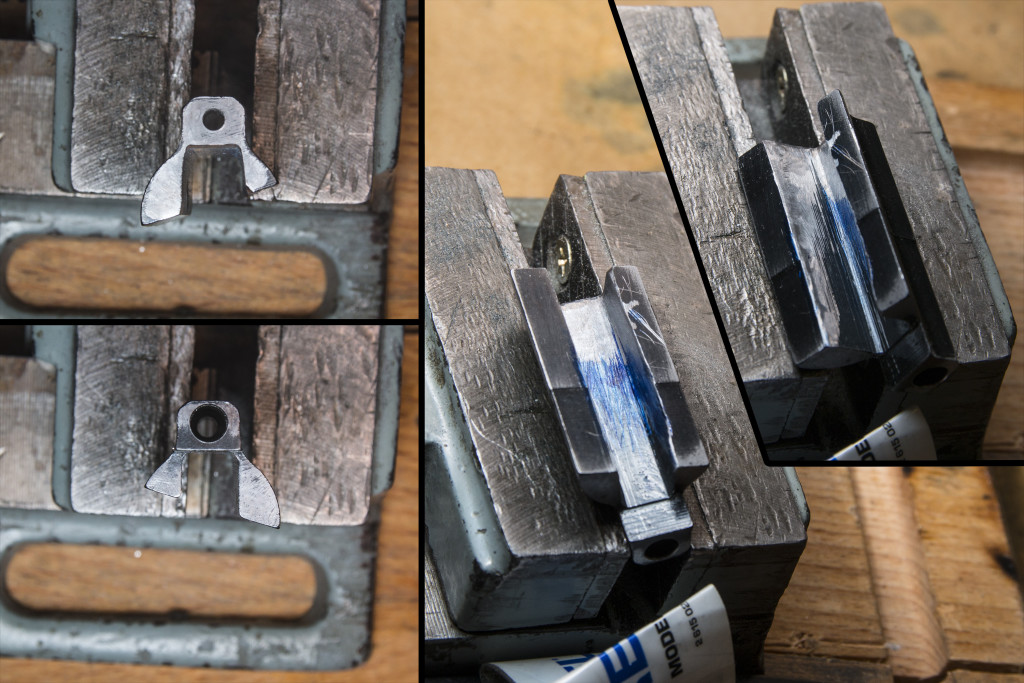

If I recall correctly, the original hammer had similar light striking issues and I am pretty confident that the issue is caused by the recoil spring guide that makes contact with the hammer, so I checked the original hammer:

As can be seen in the above image, the original hammer has taken quite a lot of contact with the recoil spring guide and only in 200 rounds. I checked the width of the original and Nord Arms triggers and the Nord Arms was actually thinner.

The manufacturer also had some “great tips” to ensure the proper functionality:

– Make sure the .22 kit is heavily lubed

Tried that, no difference between dry or heavy lubing and I have also tried different gun oils that have variable thickness.– Stretch the return spring inside the .22 carrier to add extra push

Did that, no help as the spring retracts back to normal in some time– Polish the inside face of the rails the bolt/carrier rides on

Auto-polished by shooting around 2000 rounds.– Make sure you are not riding the charging handle forward and that it has the full distance to rude forward

Not riding, the handle is locked properly and does not affect the bolt any more. Seems that they are fitted by shooting (as can be seen in the previous post).– and most importantly, you made need to adjust the notch that the charging handle latch interfaces with on the upper. The angle might be a little to steep for the handle to ride up.

I am not sure how this would affect the functionality, as the handle is locked after initial charging and after that it stays as it is (at least until the failure-to-fire occurs).

The Nord Arms hammer has very sharp edges with a little texture and this is probably the cause for it to really stick on or chip the guide/weight.

As the recoil spring guide / weight has already lost some of the edges, I decided to try to relief the traction and possible chipping between the part and the hammer, so I rounded the hammer a little.

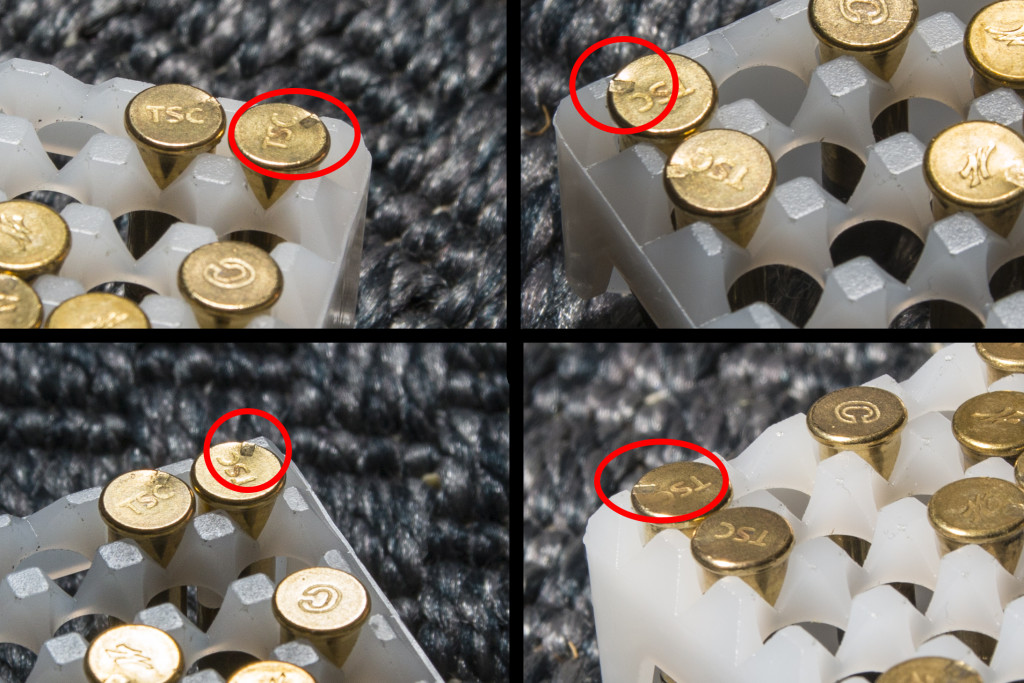

While test firing the modifications through some training stages, the functionality was almost satisfactory: only two failure-to-fires in a little over 100 rounds. Sadly the testing was interrupted when the new and enhanced firing pin broke and the original firing pin was nowhere to be found…

After a few hours of intensive “detective work”, I found the original (but slightly modified) firing pin and put it back to use, accompanied by a spring from ballpoint pen acting as firing pin spring (Part #36 in parts list by Chiappa). Some more filing/dremel also magically appeared to the recoil spring guide. I also filed a the ride side of the hammer to match the smoothness previously filed to the left side.

Top-left: front face, lower-left: rear face

Off to test firing! I shot 8 indoor IPSC stages (around 120rnds), had one failure-to-fire on the beginning second stage (around 20th shot of test fire) and after that the rest of the stages (including one mag change during the CoF) went without a hitch!

I can not remember that the gun has ever before shot over 100 rounds without any problems.

After inspecting the only faulty round, I am pretty sure that the failure was due to the round (TopShot Competition .22LR), not the gun.

Previous parts: NEA15-22 part I, part II, part III, part IV, part V

A gun is so complicated that even one malfunction or one error in one part can cause it not to work properly.