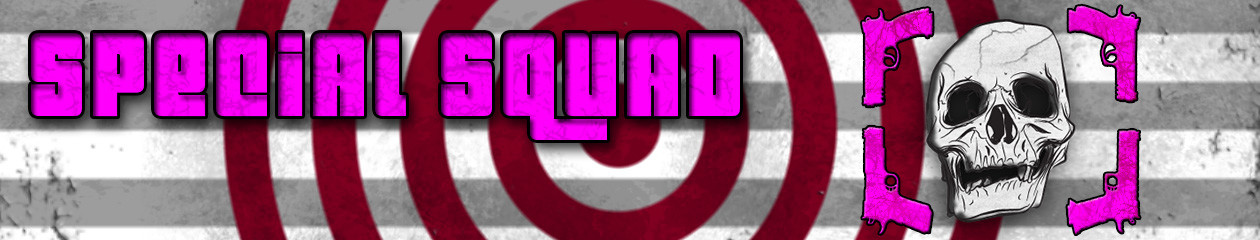

While testing the DIY Brass Catcher, there again was some failure to fires, so I took the rifle apart for checking. It seemed that there might still be too much material on the recoil spring guide / bolt weight.. So I machined (read: dremeled) off some more.

After the modifications I went to range and tested some different ammo. TopShot and CCI Standard have been working just fine, but with Federal Champion and Blazer Bulk issues appeared. Bolt was not closing properly and it was either left open just a little to prevent ignition or there was double feed and the bolt was wide open.

Apparently the Federal ammo was not as streamlined on the intersection between the brass and the bullet. So the bolt might take contact with the bullet of the next round and either there is friction to slow the bolt or it even catches the next round by the bullet while chambering the first round. This was fixed on the spot with the file found in Leatherman Multitool.

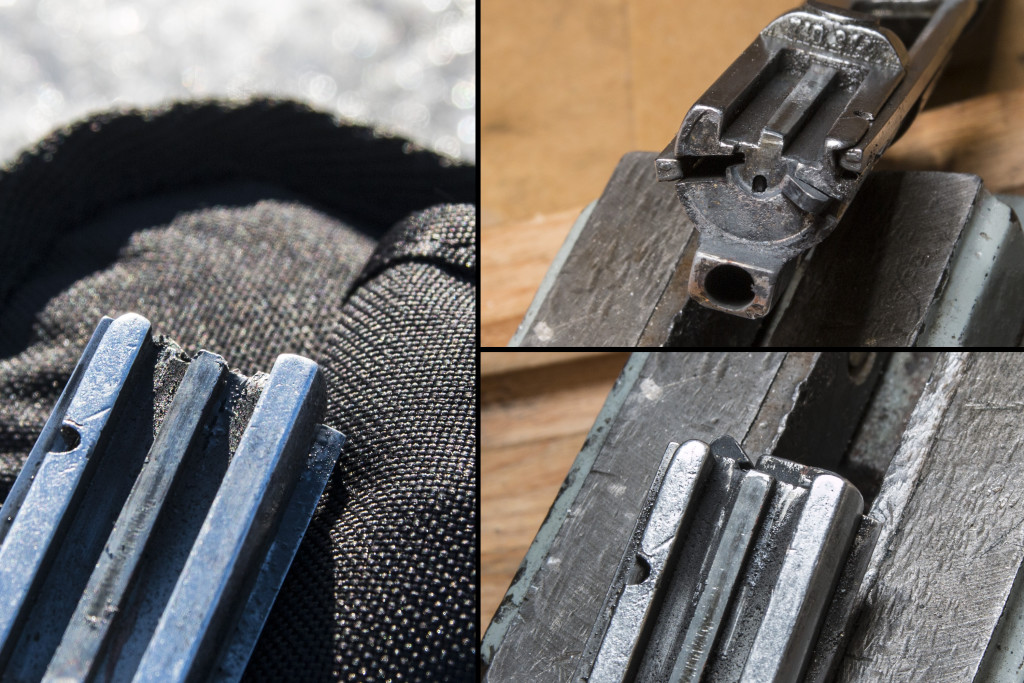

During cleaning, I also noticed that apparently the recoil spring is too weak or there should be some kind of a buffer, as the back of the action appears to have been forged by the bolt cycling.

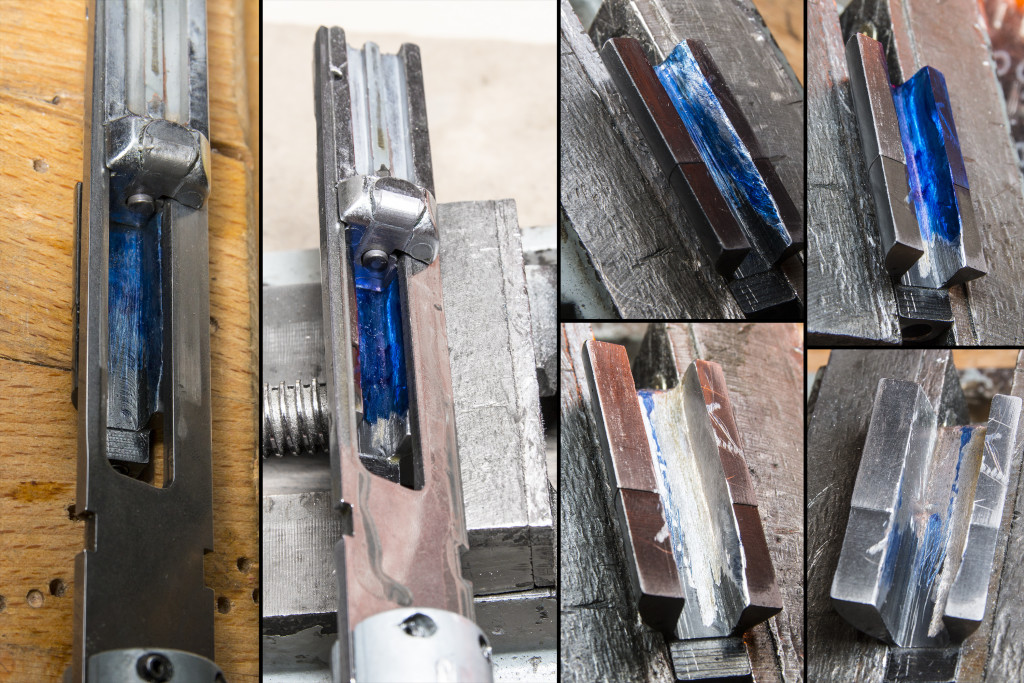

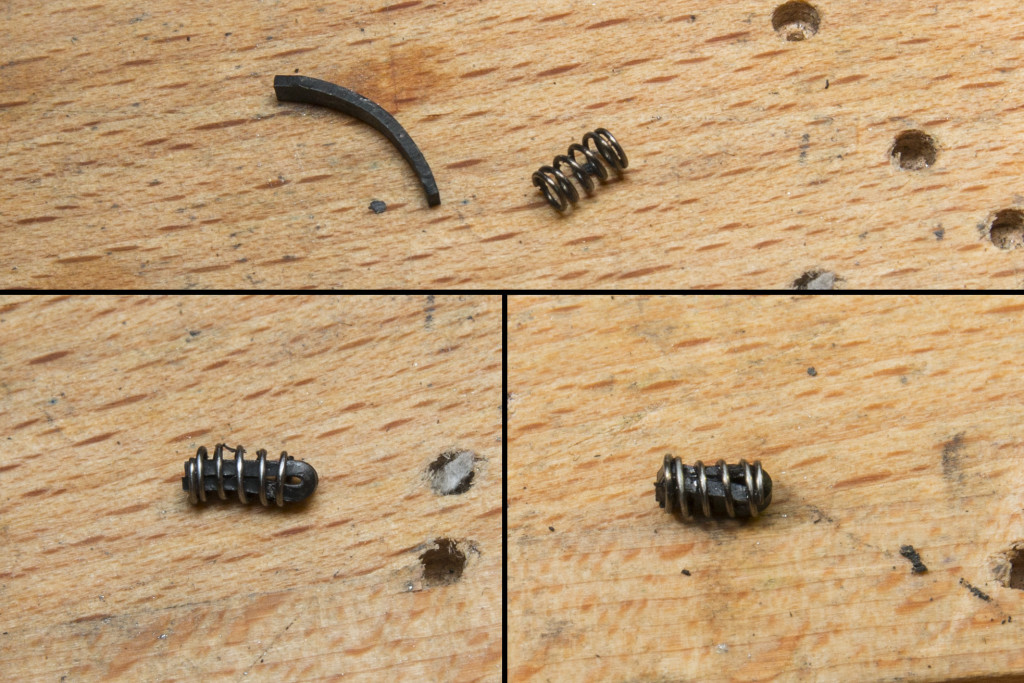

There was still some ejection problems and I tried to stiffen the spring (regular AR15 extractor spring did not fit) by adding a rubber core, cut from bicycle inner tube.

To fix the possible problem of bolt not closing properly with non-streamlined ammo or dirt, etc. I tried adding a stronger recoil spring. It just happens that Ruger 10/22 (my trusted .22lr that I look for confirmation how things should be, like with the extractor movement range) has about same diameter recoil spring as the Chiappa action found in NEA so I ordered an Enhanced Spring set for 10/22 and took the original recoil spring for NEA.

The 10/22 recoil spring is too long for Chiappa Action: when fully compressed, the bolt does not reach as back as it should be, so the spring had to be shortened. I fully compressed the srping in the action, used a marker to mark the exposed part of spring, then took it out and cut a little bit over the marked part, the resulting spring still being longer than the original.

Next time on the range the functionality was good, at least until the original firing pin broke…

So still not yet the end of the story..

Previous parts: NEA15-22 part I, part II, part III, part IV, part V, part VI